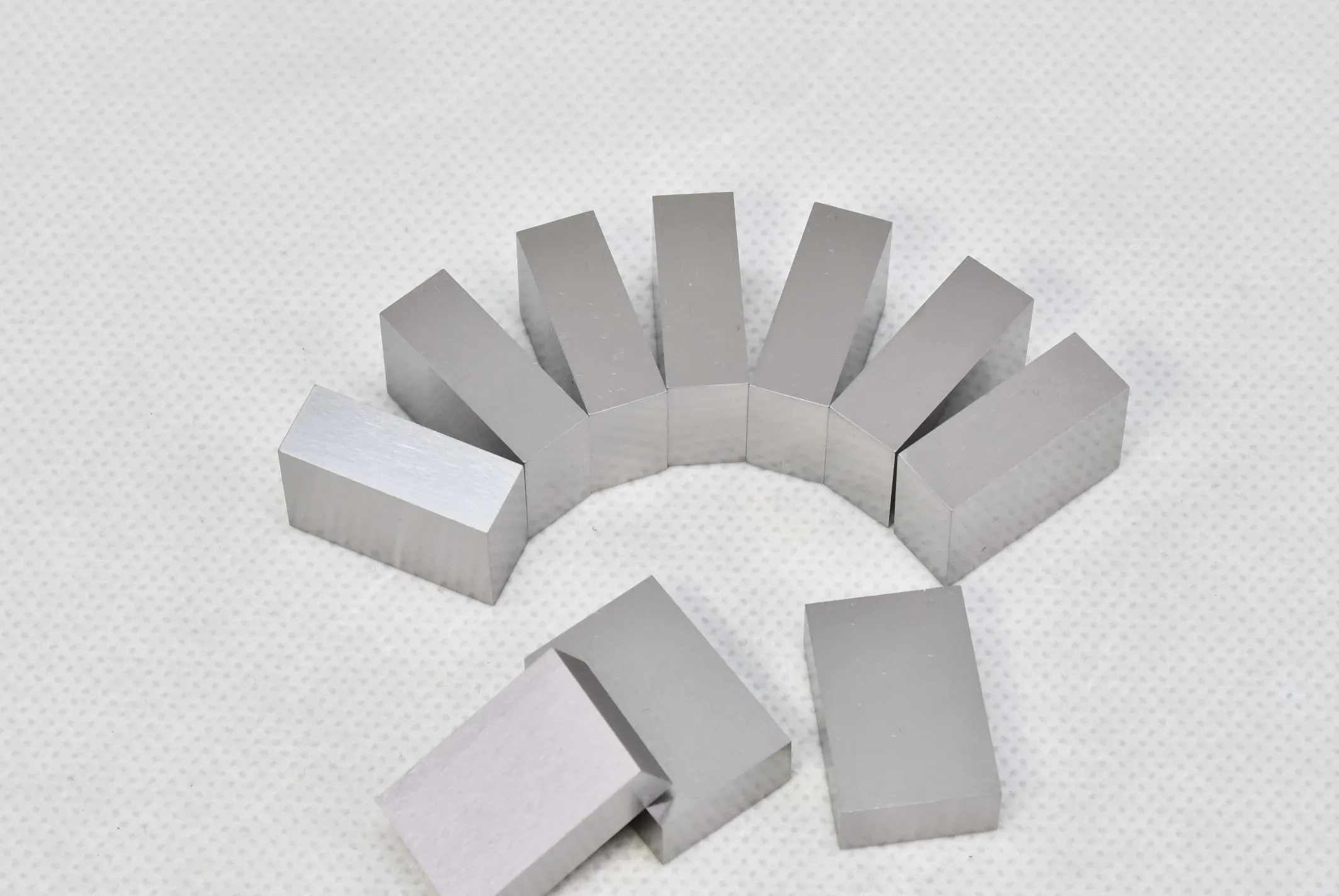

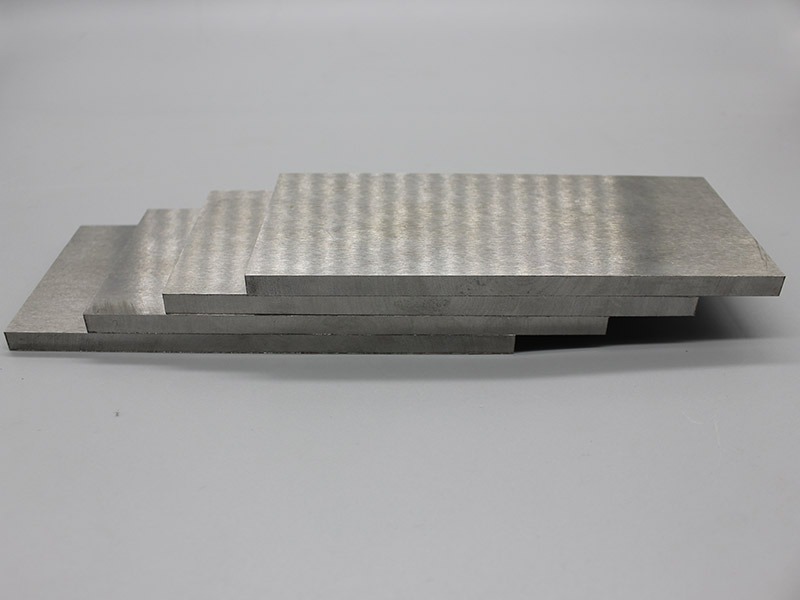

Tungsten alloy main shaft balancing block

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5pcs |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-TB-075

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 95% Tungsten

Denstiy: 18.1g/cm3

Surface: Polished

PACKAGING & DELIVERY

Selling Units : PCS

Package Type : Standard export packing

DESCRIPTION

Tungsten alloy main shaft balancing block is a high-density counterweight component customized for rotating main shafts, designed to eliminate vibration caused by mass imbalance during high-speed operation. It is widely used in precision machinery, automotive, aerospace, and other fields, with core advantages of high density, small volume, and stable performance.

1. Core Material Characteristics of Tungsten heavy alloys

The base material is tungsten-nickel-iron (W-Ni-Fe) or tungsten-nickel-copper (W-Ni-Cu) alloy, with a tungsten content of 90%–97%. This gives it the following key properties:

Ultra-high density: 16.5–18.5 g/cm³, 2.5 times that of steel and 1.7 times that of lead. It can achieve heavy counterweight effects in a small space, reducing the overall size of the balancing block.

Excellent mechanical properties: High hardness, wear resistance, and corrosion resistance, with no deformation or cracking under long-term high-speed rotation and alternating stress.

Good machinability: Can be precision-machined into various shapes (circular, rectangular, fan-shaped) and sizes to match different main shaft structures, and can be drilled, tapped, or welded for easy installation.

Non-toxic and environmentally friendly: Does not contain lead, cadmium, or other harmful substances, in line with RoHS and other environmental standards, and can replace traditional lead balancing blocks.

2. Working Principle & Functions

The main shaft of machinery will produce mass imbalance due to factors such as manufacturing errors, material unevenness, and structural asymmetry. During high-speed rotation, this imbalance will generate centrifugal force, causing vibration, noise, and accelerated wear of bearings.

Balancing principle: The tungsten alloy balancing block is installed at the designated position of the main shaft, using its high density to offset the unbalanced mass of the main shaft system, so that the center of mass of the rotating system coincides with the axis of rotation.

Core functions:

Reduce main shaft vibration and noise, improve the stability of the whole machine.

Extend the service life of bearings, gears, and other transmission components.

Ensure the precision of mechanical operation, especially suitable for high-precision equipment such as CNC machine tools and precision spindles.

3. Manufacturing Process of tungsten alloys

The production of tungsten alloy main shaft balancing blocks mainly adopts the powder metallurgy process, which is suitable for mass production and precision customization:

Powder mixing: Mix high-purity tungsten powder with nickel, iron/copper powder in a specific proportion, and add a binder to ensure uniform mixing.

Molding: Use a precision mold to press the mixed powder into a blank with the required shape (such as fan-shaped, circular ring) under high pressure (usually 100–300 MPa).

Sintering: Sinter the blank in a hydrogen atmosphere furnace at 1400–1600 °C, so that the powder particles are bonded and densified to form a high-density alloy blank.

Precision machining: Use CNC lathes, milling machines, or grinding machines to process the blank to the required size and tolerance, and process installation holes, threads, or positioning grooves according to customer requirements.

Surface treatment: Carry out anti-rust treatment (such as electroplating nickel, passivation) on the surface to improve corrosion resistance and appearance quality.

Balancing detection: Perform dynamic balancing testing on the finished product to ensure that the mass accuracy meets the application requirements.

4. Field Specific Applications of Tungsten alloy main shaft balancing block

|

Field |

Specific Applications |

|

Automotive Industry |

Engine crankshaft balancing blocks, turbocharger rotor balancing blocks, drive shaft balancing components |

|

Precision Machinery |

CNC machine tool main shafts, grinding machine spindles, high-speed motor rotors |

|

Aerospace |

Aircraft engine turbine shafts, helicopter rotor balancing blocks, satellite attitude adjustment counterweights |

|

Electrical Equipment |

High-speed fan rotors, generator main shafts, centrifugal pump impeller balancing components |

|

Medical Equipment |

High-speed rotating components of CT machines, medical centrifuges |

5. Advantages Compared with Traditional Balancing Blocks

|

Material |

Density |

Volume (Same Counterweight) |

Environmental Friendliness |

Mechanical Stability |

|

Tungsten Alloy |

16.5–18.5 g/cm³ |

Smallest |

Non-toxic, recyclable |

High hardness, no deformation |

|

Steel |

7.8 g/cm³ |

Largest |

Environmental friendly |

Low strength, easy to wear |

|

Lead |

11.3 g/cm³ |

Medium |

Toxic, restricted use |

Soft, easy to deform |

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU